Hey! Sure You Don’t Want To Take A Look At Our POY Production Line?

Last week, we talked about the excellent performance of FDY Line and the meticulous service that CTMTC provide. This week, we will introduce you about CTMTC’s POY Line.

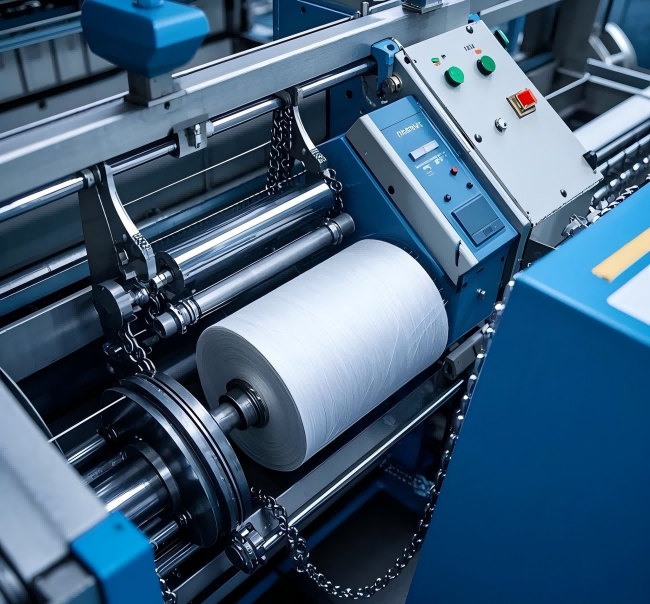

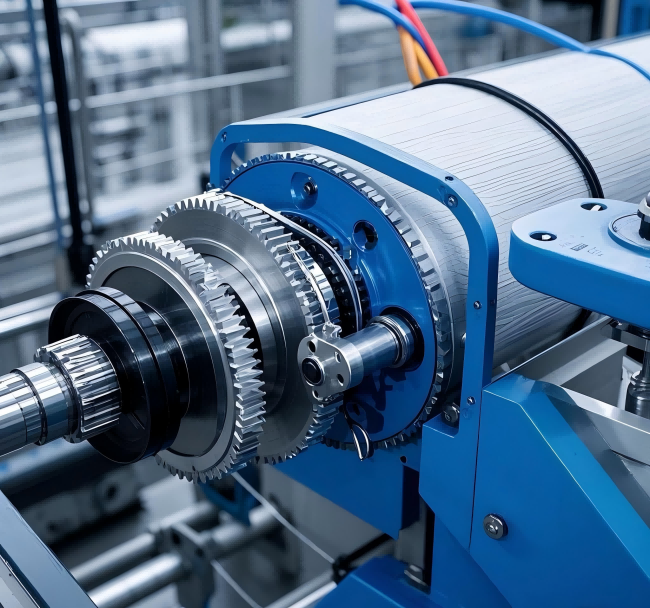

Let’s first understand the principle of the production of POY, in fact, it is very simple: Poy production line is a key equipment for the production of pre-oriented silk (POY), a partially oriented polyester filament, widely used in the textile field. Poy textile machinery will be plastic melt under extremely high pressure through the micro spinner hole press out, form a single filament combined into a tow, through the wire guide roller stretching, and through the winding head winding into a silk cake. Compared with other textile machinery, POY machinery has significant characteristics. Polyester POY spinning machine adopts polyester special screw extruder, AC frequency conversion speed regulation, new continuous switching filter and mixed uniform melt pipeline, complete structure, convenient disassembly of spinning components, accurate calculation of planetary gear pump and lift stretch quick disassembly transmission rod, uniform and stable side blowing device, suitable for spinning polyester spray oil system, domestic manual or automatic switching winding machine.

Sounds simple, but it is very difficult to master the technology with high precision and at the same time extremely high stability, and CTMTC can do that. POY silk can be widely used in knitted fabrics, woven fabrics, home textiles and other fields, the processing speed of the POY production line provided by CTMTC can reach 2700-3200 meters/min, and the maximum length of the bottom can reach 1800 mm, which is actually the industry leader. In addition, as the core of the POY production line, the winder has an exceptionally soft touch to achieve the outstanding uniformity, filament tension and CV% values you need. More importantly, as the leader of POY spinning machines, CTMTC cooperates with world-renowned brands on key parts, such as SIEMENS, FESTO, FAG, SMC, etc., in order to ensure the top quality of yarn and achieve energy saving and emission reduction.

Choose CTMTC, we will provide you with personalized design and the whole process of the solution, including but not limited to: feasibility study report, professional design, high-quality textile machinery, meticulous on-site installation and commissioning, staff training, etc. Select CTMTC, successful selection!