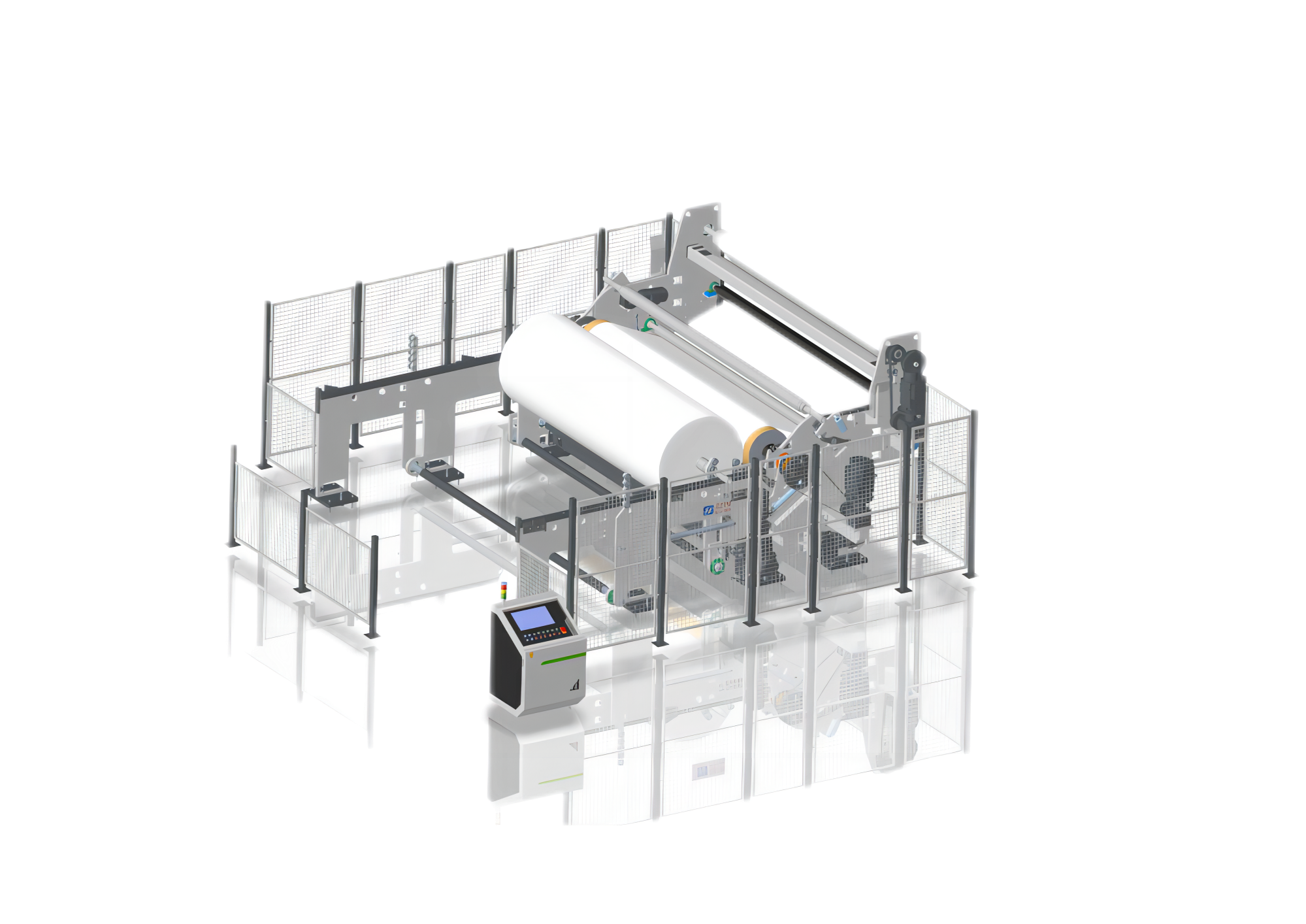

Spunlace Nonwoven Machine from CTMTC – 5 Winder

The primary function of the non-woven fabric winding machine is to wind wide-width non-woven fabric materials into rolls for the purpose of convenient storage, transportation, and subsequent processing.

Typically, the winding machine is interconnected with other equipment in the non-woven fabric production line, such as traction machines and hydroentanglement machines.

Structure: A non-woven fabric winding machine typically consists of components such as the frame, winding shaft, tension control system, automatic cutting device, and winding control system. The winding shaft serves as the core component for winding non-woven fabric and can be adjusted in diameter and width as needed.

Operating Principle: During the operation, non-woven fabric is conveyed from the front-end supply device to the winding shaft. The uniform winding is achieved through the winding control system. Simultaneously, the tension control system ensures that the non-woven fabric maintains an appropriate level of tension during the winding process to prevent slack or damage.

Automatic Cutting: Some advanced non-woven fabric winding machines are equipped with an automatic cutting device. This device can cut the wound rolls to the desired length based on pre-set specifications for subsequent processing.

Control System: Winding machines are typically equipped with advanced electrical control systems that enable automation. These systems allow for the adjustment and monitoring of parameters such as winding speed, tension, and winding length.

Applications: Non-woven fabric winding machines find wide applications in the non-woven fabric manufacturing industry, including the production of medical supplies, sanitary napkins, textiles, filtration materials, and more. They can accommodate various widths and diameters of rolls.

Specific Parameters:

The specific parameters of a non-woven fabric winding machine may vary depending on the manufacturer, model, and intended use. Here are some example parameters:

Max. Roll Diameter: Typically between 200 millimeters (about 8 inches) and 800 millimeters (about 31 inches), depending on the machine model and application.

Max. Roll Width: May range from 1500 millimeters (about 59 inches) to 5000 millimeters (about 197 inches), depending on the machine model.

Rolling Speed: Typically between 10 meters per minute (about 33 feet per minute) and 300 meters per minute (about 984 feet per minute), depending on the machine model.

Core Diameter: Usually between 50 millimeters (about 2 inches) and 152 millimeters (about 6 inches), depending on the machine model.

Winding Mode: Options may include single-sided winding, double-sided winding, alternate winding, etc., depending on the machine’s design and purpose.

Cutting Mode: Some machines may be equipped with an automatic cutting device for on-demand cutting.

Tension Control: Typically includes adjustable tension control systems to ensure proper tension during winding.

Control System: Includes a touchscreen interface, PLC (Programmable Logic Controller), etc., for automation and control.

Power Requirements: May require voltage, frequency, and power specifications, typically three-phase power.

Weight and Dimensions: Physical dimensions and weight vary based on the model and design, requiring consideration for layout and installation in a factory.

the non-woven fabric winding machine, as part of the non-woven fabric production line, plays a crucial role in enhancing production efficiency and ensuring the quality of non-woven fabric rolls. It is applicable across a range of non-woven fabric product manufacturing processes.

Please connect with CTMTC if there are needed on the machine.